Putting humans on Mars has been one of NASA’s driving missions for years, but they are still in the early stages of deciding what exactly that mission architecture will look like. One major factor is where to get the propellant to send the astronauts back to Earth. Advocates of space exploration often suggest harvesting the necessary propellant from Mars itself – some materials can be used to create liquid oxygen and methane, two commonly used propellants. To support this effort, a group from NASA’s COMPASS team detailed several scenarios of the infrastructure and technologies it would take to make an in-situ resource utilization (ISRU) system that could provide enough propellant to get astronauts back to a Mars orbit where they could meet up with an Earth return vehicle. However, there are significant challenges to implementing such a system, and they must be addressed before the 8-9-year process of getting the system up and running can begin.

To understand these challenges, it’s first essential to understand some of the requirements the team was trying to meet. The goal was to provide 300 tons of liquid oxygen and liquid methane to a Mars Ascent and Landing Vehicle (MALV) being developed at other parts of NASA. That much propellant is necessary to get a crew of astronauts back into orbit, where they can be met by an orbiting Earth return vehicle.

Creating liquid oxygen and methane requires many ISRU systems, such as pumps, electrolyzers, dryers, scrubbers, and significant power systems, to run all these machines. Some raw materials, such as CO2, can be pulled from the Martian atmosphere. However, the system will also require 150 tons of water, which could be trucked in from Earth or harvested from Mars.

Designing the overall system architecture is the first step in determining the best method for getting enough propellant to get the astronauts back off of Mars. A paper from the group compares five different approaches to solving that problem and details three of them, focusing on three different methods of getting water to use in the creation of liquid propellants on the surface of Mars.

Let’s first look at the two options for extracting water locally on Mars. One architecture uses a borehole drill to melt subsurface ice and pump it back to the surface, which can be used in electrolysis. The other architecture uses surface harvesting techniques, where soil with a high frozen water content can be sorted, and the water itself melted to provide sufficient stockpiles for creating propellant.

Drilling a borehole deep enough to access subsurface ice has never been done before. It does have some advantages over other water collection methods, including taking less time and requiring one less MALV delivery of equipment (i.e., making it lower cost). However, it does require more power plants and some specialized equipment to be developed.

Collecting water from surface regolith utilizes some technologies already being developed at NASA – including the RAZZOR surface mining system that could be used on the Moon or Mars. However, it requires as much time and as many launches as shipping water from Earth, with many possible unknown failure points in the architecture.

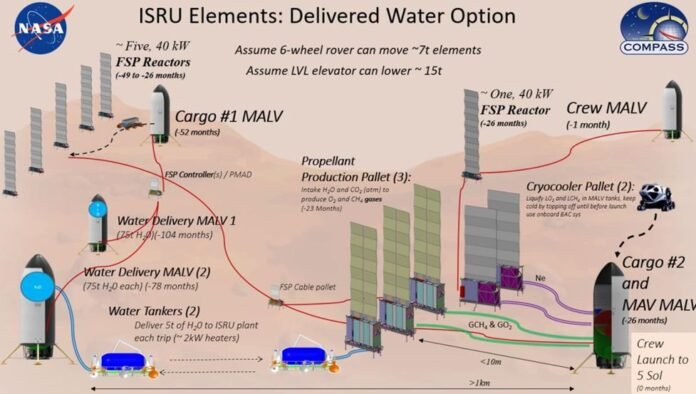

By comparison, sending 150 tons of water directly from Earth, while it might be expensive in terms of launch costs, simplifies the overall architecture significantly. There would still technically be ISRU in this scenario, as the water would still be used to create propellant from local Martian resources. However, the added step of getting that water locally would be eliminated.

Even that is a more complicated process than the other two options the team considered, without as much detail in the paper as the actual ISRU setups. Mission designers could send either the methane or both the methane and oxygen from Earth directly, bypassing the need for any ISRU to happen. While these options require potentially more MALV landers, their overall risk is minimized, as the necessary chemicals would be available for use at any point the astronauts would need them. However, they would take longer to set up – especially the option of sending all of the propellants directly from Earth, which could take upwards of 10 years to get set up.

Other challenges abound for utilizing Martian resources to create propellants – including limited locations where the necessary water may be found. This geographical restriction might not overlap with where astronauts might be needed to do exciting science, so the architects would have to prioritize either scientific discovery or derisking the ISRU equipment – they likely couldn’t do both.

So, all things considered, if the purpose is to send people to Mars and back safely, it seems like the best, most reliable option is to send the total amount of propellant from Earth. However, in the long run, if humanity plans to make a sustainable presence on Mars, we will need to utilize local resources. The paper from the COMPASS team clearly defines a few strategies that could do that, and someday, it will become the better option – just maybe not quite yet.

Learn More:

Oleson et al – Kiloton Class ISRU Systems for LO2/LCH4 Propellant Production on the Mars Surface

UT – A Single Robot Could Provide a Mission To Mars With Enough Water and Oxygen

UT – Resources on Mars Could Support Human Explorers

UT – Mars Explorers are Going to Need air, and Lots of it. Here’s a Technology That Might Help Them Breath Easy

Lead Image:

Architecture Design of the water from Earth delivery option.

Credit – Oleson et al. / NASA